-

Fiber Laser Cleaning Machine

-

Handheld Laser Cleaning Machine

-

Backpack Laser Cleaning Machine

-

Fiber Laser Cutting Machine

-

Tube Laser Cutting Machine

-

Metal Laser Cutting Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Welding Machine

-

Battery Laser Welding Machine

-

Jewelry Laser Welding Machine

-

YAG Laser Welding Machine

-

Laser Marking Machine

-

Fiber Laser Source

-

Laser Cutting Head

-

Laser Control System

-

Laser Equipment Parts

-

Robot Laser

-

Industrial Laser Solutions

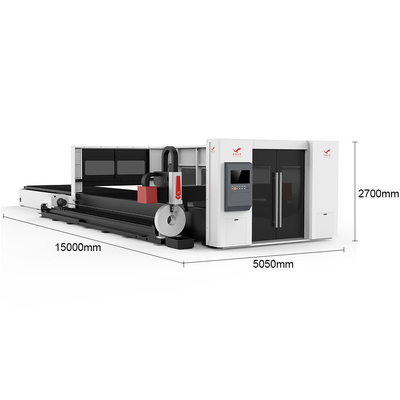

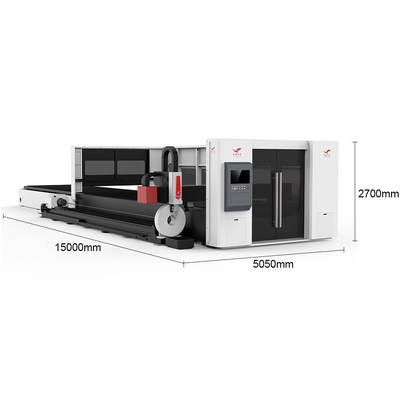

6025 1000W-20000W Fiber Tube Laser Cutting Machine Cypcut Hypcut Beckhoff Optional

| Place of Origin | China |

|---|---|

| Brand Name | DP LASER |

| Certification | CE SGS FDA TUV ROHS |

| Model Number | Laser Cutting Machine |

| Minimum Order Quantity | 1 Set |

| Price | Please contact us |

| Packaging Details | Wooden boxes that meet international export standards |

| Delivery Time | 10-30 Work Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 300 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Laser Source | Raycus Max IPG NLIGHT Optional | Laser Power | 1000W-20000W |

|---|---|---|---|

| Laser Head | Raytools Precitec WSX OSPRI Optional | Control System | Cypcut Hypcut Beckhoff Optional |

| Feature | SERVO-MOTOR | Configuration | 4-axis |

| Maximum Acceleration | 1.5G | Cutting Speed | 150m/min |

| Power Supply | 380V/50HZ | After-sales Service Provided | Overseas Engineers Provide Door-to-door Service |

| High Light | 1kw fiber tube laser cutting machine Hypcut,fiber tube laser cutting machine Cypcut,6025 fiber laser tube cutter Beckhoff |

||

6025 1000W-20000W Metal Sheet And Tube Integration Fiber Laser Cutting Machine

Features

Application industry

Widely used in kitchen appliances, sheet metal chassis cabinets, mechanical equipment, electrical equipment, lighting hardware, advertising signs, auto parts, display equipment, various metal products, sheet metal cutting and other industries. It can cut various metal plates and pipes, mainly used for rapid cutting of stainless steel, carbon steel, manganese steel, galvanized sheet, various alloy sheets, rare metals and other materials.

![]()

Features of our Laser Cutting Machines

1. Integrated casting machine body with higher stability for higher precision.

Application of gantry structure and integrated cast cross-girder to achieve higher rigidity, stability, shock resistance.

2. High-performance laser source and stable operating system which make the best cutting effect.

3. The machine owns perfect cooling system, lubrication system and dust removal system, to ensure that it can operate stably, efficiently and durably.

4. The machine is capable of automatic height adjustment to maintain constant focal length and stable cutting quality.

5. The machine is used for cutting a variety of metals with excellent and stable cutting quality.

6. The specialized CAD / CAM automatic programming software and automatic nesting software aim to maximally save raw materials.

7. Access to the CNC system through Ethernet interface makes communication and remote monitoring possible during the laser cutting process. owns perfect cooling system, lubrication system and dust removal syst.

![]()

| Cutting Sheet Metal Parameters | |||||

| Working Area | 2500*1300 | 3000*1500 | 4000*1500 | 4000*2000 | 6000*1500 |

| X/Y Axis Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y Axis Repositioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. Moving Speed | 150m/min | 150m/min | 150m/min | 150m/min | 150m/min |

| Max.Acc Speec | 1.5G | 1.5G | 1.5G | 1.5G | 1.5G |

| Laser Power | 1000W-1500W | 1000W-6000W | 1500W-6000W | 1500W-6000W | 1500W-6000W |

| Laser Source | RAYCUS IPG nLIGHT MAX (Optional) | ||||

| Laser Cutting Head | PRECITEC RAYTOOL WSX OSPRI (Optional) | ||||

| Working Area | 6000*2000 | 6000*2500 | 8000*2500 | 10000*2500 | 12000*2500 |

| X/Y Axis Positioning Accuracy | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm | ±0.03mm |

| X/Y Axis Repositioning Accuracy | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm | ±0.02mm |

| Max. Moving Speed | 300m/min | 300m/min | 300m/min | 300m/min | 300m/min |

| Max.Acc Speec | 5.0G | 5.0G | 5.0G | 5.0G | 5.0G |

| Laser Power | 3000W-12000W | 3000W-20000W | 6000W-20000W | 6000W-20000W | 6000W-20000W |

| Laser Source | RAYCUS IPG nLIGHT MAX (Optional) | ||||

| Laser Cutting Head | PRECITEC RAYTOOL WSX OSPRI (Optional) | ||||

| Cutting Metal Tube Parameters | |||||||

| Model | 6012 | 6016 | 6022 | 6032 | 6035 | 6040 | 6052 |

| Outer Diameter | Φ430 | Φ590 | Φ600 | Φ760 | Φ844 | Φ950 | Φ1140 |

| Through Hole Diameter | Φ130 | Φ170 | Φ225 | Φ325 | Φ365 | Φ400 | Φ520 |

| Processing Range | 10-120 | 10-160 | 15-218 | 15-320 | 20-350 | 20-400 | 20-508 |

| Repositioning Accuracy | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 |

| Rotation Accuracy | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.10 |

| Minimum Clamping Wall Thickness | ≥1 | ≥1 | ≥1 | ≥1 | ≥2 | ≥3 | ≥5 |

| Rated Speed | 150rmp | 100rmp | 150rmp | 100rmp | 50rmp | 50rmp | 50rmp |

The metal laser cutting machine adopts a reinforced welding bed, which undergoes tempering treatment and vibration aging treatment to eliminate stress, and then performs fine milling processing on a large-scale gantry milling machine to ensure long-term stability and no deformation of the machine tool. It is equipped with high-performance original packaged fiber lasers with stable performance. , The service life can reach 100,000 hours. It adopts imported guide drive and servo motor, and can use auxiliary gas (oxygen, argon, nitrogen) to cut various metal sheets, easy to operate, high precision, high speed and high efficiency.

![]()

![]()

![]()