-

Fiber Laser Cleaning Machine

-

Handheld Laser Cleaning Machine

-

Backpack Laser Cleaning Machine

-

Fiber Laser Cutting Machine

-

Tube Laser Cutting Machine

-

Metal Laser Cutting Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Welding Machine

-

Battery Laser Welding Machine

-

Jewelry Laser Welding Machine

-

YAG Laser Welding Machine

-

Laser Marking Machine

-

Fiber Laser Source

-

Laser Cutting Head

-

Laser Control System

-

Laser Equipment Parts

-

Robot Laser

-

Industrial Laser Solutions

Precitec ProCutter Zoom 2.0 12KW Fiber Laser Cutting Head For Fiber Laser Cutting Machine

| Place of Origin | China |

|---|---|

| Brand Name | DP LASER |

| Certification | CE SGS FDA TUV ROHS |

| Model Number | Laser Cutting Head |

| Minimum Order Quantity | 1 Set |

| Price | Please contact us |

| Packaging Details | Wooden boxes that meet international export standards |

| Delivery Time | 7-15 Work Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 300 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand | Precitec | Product Name | Fiber Laser Cutting Head |

|---|---|---|---|

| Laser Type | Fiber Laser | Feature | High Efficiency |

| Application | Metals Cutting | Condition | New |

| Weight (KG) | 7.6 KG | Machinery Test Report | Provided |

| Video Outgoing-inspection | Provided | After-sales Service | Overseas Engineers Provide Door-to-door Service |

| High Light | Precitec fiber laser cutting head,12KW fiber laser cutting head |

||

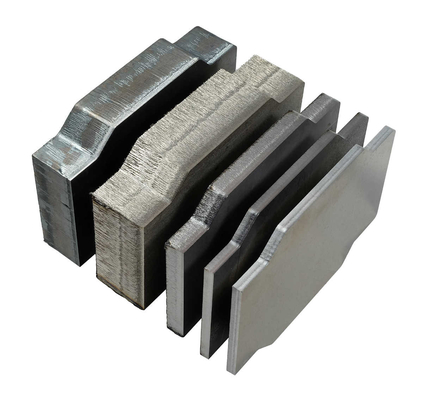

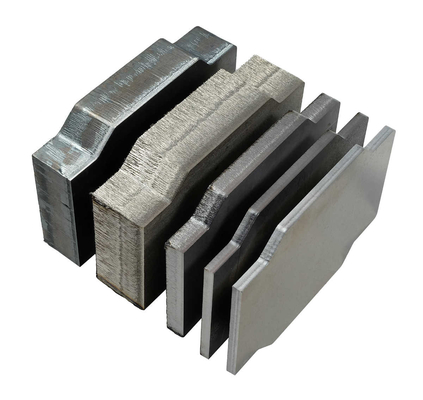

Precitec ProCutter Zoom 2.0 12KW 12000W Fiber Laser Cutting Head For Fiber Laser Cutting Machine

Basic introduction

Laser cutting head is a new technology that has been applied to various industries, including metal cutting, glass cutting and engraving, etc.

1.Maximum flexibility and highest output

With the cutting head you always achieve the optimum process results - both in terms of quality and speed. Thanks to the extensive traverse paths and variable magnification of the laser spot, the optimum cutting and piercing process can be set for every type and thickness of material. Compared to a product with fixed magnification, this results in speed advantages of up to 35% in some areas of laser cutting.

The extensive traverse paths are particularly advantageous when processing thick materials. New processes can be applied in a stable manner, resulting in excellent roughness and squareness of the component.

2.Reduction of rework & lower unit costs

The component quality and process stability also benefit equally from the variable magnification of the laser spot. Fluctuations in the process or in the quality of the material to be cut are compensated without the need for intervention by the machine operator. Splashes are avoided when piercing the material and the duration is shortened. The component surface remains unaffected, wearing parts are spared, and the follow-up costs are reduced. A wide range of sensors, which provide permanent information on the condition of the core components, reduces the number of machine downtimes.

|

ProCutter 2.0 Zoom Laser Cutting Up To 12KW |

ProCutter 2.0 Zoom

The cutting head ProCutter Zoom 2.0 provides a maximum and flexible performance in a minimum of space. It generates the perfect beam for all materials in all thicknesses for laser powers up to 12 kW and is therefore the ultimate all-rounder for your flatbed system.

![]()

![]()

![]()

Technical data

| Max. laser power | 12 kW (with wave lengths of 1030 - 1090 nm) |

| Magnification ratio | 1.2 / 1.5 / 2.0 / 2.5 / 3.0 / 3.5 / 4.0 |

| NAmax | 0.13 |

| Dimensions (WXD) | 126 x 133 mm |

| Weight | 7.6 kg |

![]()

![]()

![]()

![]()

![]()

![]()