-

Fiber Laser Cleaning Machine

-

Handheld Laser Cleaning Machine

-

Backpack Laser Cleaning Machine

-

Fiber Laser Cutting Machine

-

Tube Laser Cutting Machine

-

Metal Laser Cutting Machine

-

Handheld Laser Welding Machine

-

Fiber Laser Welding Machine

-

Battery Laser Welding Machine

-

Jewelry Laser Welding Machine

-

YAG Laser Welding Machine

-

Laser Marking Machine

-

Fiber Laser Source

-

Laser Cutting Head

-

Laser Control System

-

Laser Equipment Parts

-

Robot Laser

-

Industrial Laser Solutions

Hypcut Bus-Type Dedicated Laser Control System FSCUT 8000A High Power

| Place of Origin | China |

|---|---|

| Brand Name | DP LASER |

| Certification | CE SGS FDA TUV ROHS |

| Model Number | Laser Control System |

| Minimum Order Quantity | 1 Set |

| Price | Please contact us |

| Packaging Details | Wooden boxes that meet international export standards |

| Delivery Time | 7-15 Work Days |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability | 300 set/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand | FSCUT | Product Name | Cypcut Laser Control |

|---|---|---|---|

| Software | Hypcut | Used For | Fiber Laser Cutting Machine |

| Package | Carton | Application | Metals Cutting |

| Warranty | 1 Year | Machinery Test Report | Provided |

| Weight (KG) | 10 KG | After-sales Service | Overseas Engineers Provide Door-to-door Service |

| Highlight | FSCUT 8000A Laser Control System,Hypcut Laser Control System |

||

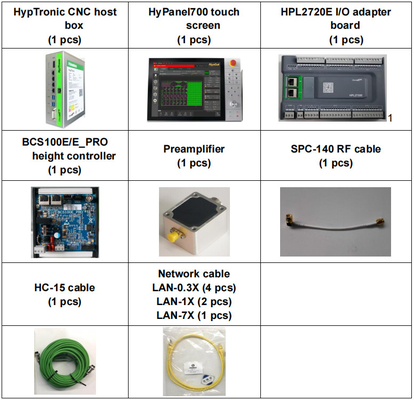

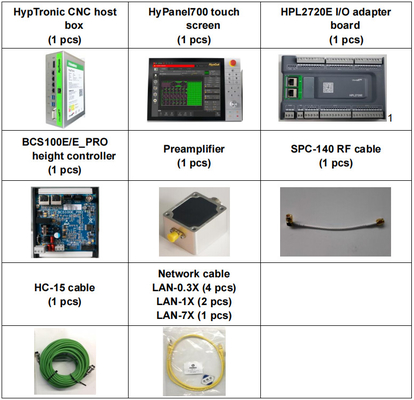

FSCUT 8000A High Power Hypcut Bus-Type Dedicated Fiber Laser Cutting Machine Control System

Basic introduction

FSCUT8000 system is a high-end intelligent bus system for ultra-high power fiber laser cutting requirements of 8KW and above. It has the characteristics of stability and reliability, convenient deployment, easy debugging, safe production, rich functions, and excellent performance; it supports and provides modular, personalized, automated, and information-based solutions. At present, there is a relatively mature and high-end bus-type dedicated laser cutting system on the market.

Feature

1.Function

Process: Non-inductive perforation for medium and thin plates, lightning perforation for thick plates, multi-level perforation, perforation and slag removal, follow-up vibration suppression, air pressure closed-loop, and layer-by-layer fine technology, etc., greatly improve the efficiency and stability of high-power cutting, and improve the core competitiveness of equipment force.

Visual residual material: Combined with mobile phone photo layout, machine tool visual positioning realizes ultra-efficient recycling and reuse of residual material.

Capacitor edge-finding: 500mm/s high-speed and high-precision capacitor edge-finding, and also provides manual, two-point, three-point, four-point and other edge-finding methods to meet the requirements of special-shaped material edge-finding and higher-precision edge-finding.

Drawing format support: support the direct output processing of original ecological DXF, G code and other drawings; support high-speed read and write operations and processing of LXDS and NRP special files output by CypNest.

UI: guided, visual interaction, easy to learn.

Automation: Supports automation solutions such as online coil cutting, double-head coil cutting, integrated tube-sheet cutting, and ultra-large format sub-regional processing to meet more market development.

Convenient maintenance: provide product operation data such as focus test & calibration, photo paper detection of optical path pollution, and oscilloscope monitoring servo.

Informatization: Connect to Baichu Health Cloud, mes and other systems, collect the use status of equipment components, and intelligently analyze and remind equipment maintenance to prolong the service life of equipment.

Drawing: You can directly draw or edit the graphic track in the HypCut processing system without the cooperation of third-party software, which improves the efficiency of debugging and adjustment.

Convenient functions: provide standard modular functions such as one-key cutting, cleaning nozzles, automatic calibration, automatic lubrication, exchange of worktables, and sub-regional dust extraction, adding more selling points to the equipment.

2.Control related

BC-LINK: Self-developed BC-LINK communication technology to achieve anti-interference and ultra-long-distance transmission of display signals, IO signals, and USB signals.

Servo PID self-optimization: One-click to complete the servo parameter debugging, the theoretical control progress is within ±0.01mm.

Intelligent hardware: support bus proportional valve, laser and intelligent cutting head, realize full closed loop 1+1>2 effect, improve performance and stability.

Safety: torque deviation anti-collision protection, real-time calibration of dual-drive balance, air-moving obstacle avoidance, intelligent frog leaping and other functions.

Accuracy: Theoretical trajectory accuracy is ±0.005mm, positioning accuracy is 0.01mm, and repeat positioning accuracy is 0.01mm.

Speed: maximum support 5G acceleration, maximum single axis speed 300m/min.

Communication: The RTOS real-time system solution is adopted, and the communication cycle is shortened to 1ms.

Algorithm: Provide an asymmetric acceleration and deceleration algorithm to make the device run fast and soft, and improve the service life of the device.

Height adjustment: The high-performance BCS100 height controller is upgraded to a bus real-time follow-up system, which further improves the follow-up stability and performance.

Applicable Industries

Suitable for ultra-high power fiber laser cutting machines above 8000W. Widely used in sheet metal factories, automated production lines, and large processing stations.

| FSCUT 8000A |

![]()

![]()

![]()

![]()

![]()